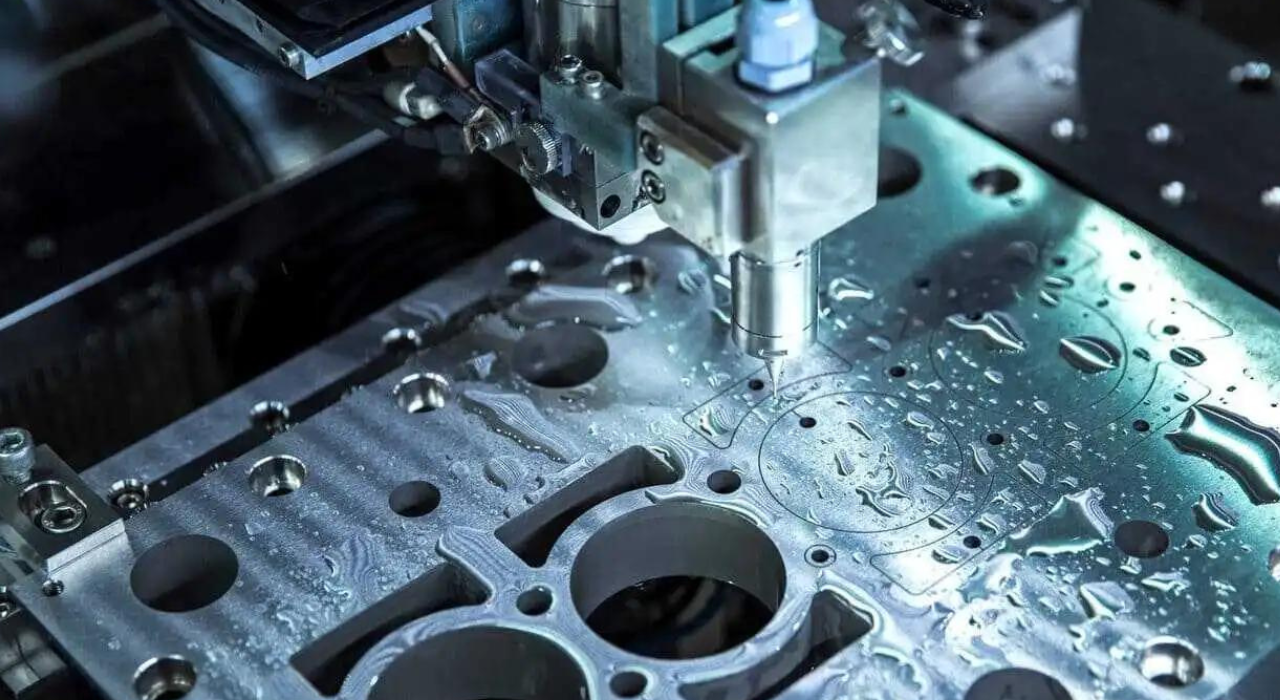

CNC (Computer Numerical Control) machining could be a preparation utilized in fabricating to control machine instruments through computer frameworks. The determination of fabric plays a vital part in CNC machining, influencing not as it were the machining handle but also the general costs. Understanding how diverse materials impact the costs can assist producers make educated choices, optimizing their generation forms, and accomplish cost-effectiveness without compromising on quality. You may visit this link https://www.longshengmfg.com/calculating-cnc-machining-costs/ for more information.

The Affect of Fabric Determination on CNC Machining Costs

The choice of fabric in CNC machining altogether influences costs through its impact on tooling, machining parameters, crude fabric costs, squander administration, and quality control. Understanding these variables makes a difference in producers optimizing generation forms, adjusting execution, and quality, and taking a toll for proficient and economical outcomes.

Hardness

Hardness may be a key property that influences how effortlessly a fabric can be machined. Materials like stainless steel and titanium are much harder than aluminum or plastic. Harder materials by and large require more vigorous and wear-resistant tooling, leading to expanded apparatus wear and substitution costs. Furthermore, harder materials regularly require slower machining speeds and more passes, which increases machining time and costs.

Sturdiness and Quality

Materials with tall sturdiness and quality, such as certain steels and combinations, can be more troublesome to machines due to the expanded resistance they offer against cutting strengths. This resistance can cause higher control utilization, expanded device wear, and more visit upkeep of the machining gear. These variables in total drive up the costs related to CNC machining.

Warm Properties

The warm properties of materials, counting warm conductivity and development, affect the machining handle. Materials with destitute warm conductivity, such as titanium, can hold warm amid machining, driving to warm twisting and potential harm to both the apparatus and the workpiece. This requires the utilization of specialized cooling frameworks and methods, including the generally taken toll.

Instrument Fabric and Coatings

The choice of device fabric and coatings is basic when machining distinctive materials. High-speed steel (HSS) instruments may be adequate for gentler materials like aluminum or plastic, but harder materials regularly require carbide or indeed diamond-coated apparatuses. These progressed devices are essentially more costly but essential to attain wanted machining comes about and amplify apparatus life when managing challenging materials.

Instrument Geometry and Plan

Device geometry, counting the cutting edge, point, and plan, must be optimized for the particular fabric being machined. Complex geometries and exact resiliences required for harder or more delicate materials may require custom apparatuses or progressed apparatus plans. Custom apparatuses can be costly to create and keep up, in this way expanding the general machining costs.

Cutting Speed and Nourish Rate

The cutting speed and bolster rate must be carefully chosen based on the materialâs properties. Milder materials can ordinarily be machined at higher speeds and nourish rates, decreasing machining time and costs. In differentiation, harder or more rough materials require lower speeds and bolster rates to dodge intemperate device wear and keep up quality, coming about in longer machining times and higher costs.

Cooling and Oil

Viable cooling and lubrication are essential in CNC machining to oversee warm and diminish grinding. Distinctive materials have shifting necessities for cooling and oil. For occasion, machining metals like steel or titanium regularly requires progressed coolant frameworks and particular greases, which include operational costs. In differentiation, machining plastics or milder metals may require negligible or standard cooling arrangements, in this way being less costly.

Crude Fabric Fetched

The fetched of crude materials may be a coordinate figure within the general machining fetched. High-performance materials like aerospace-grade titanium or specialized amalgams are essentially more costly than common materials like aluminum or gentle steel. This distinction in fabric fetching can substantially affect the general budget of a CNC machining venture.

Conclusion

Fabric determination could be an essential figure in CNC machining, impacting different perspectives of the machining preparation and the related costs. From the inalienable properties of the fabric, tooling necessities, machining parameters, fabric taking a toll, and accessibility, to squander administration and quality control, each component plays a part in deciding the general cost-effectiveness of a machining extend.